Selecting the Best GaN Gate Driver

GaNの話 – Chang-Woo Ryu

11 14, 2023

In this blog we discuss the key factors engineers should consider when trying to choose the best GaN gate driver for their project.

Gallium Nitride (GaN)’s Advantages in Power Electronics

Gallium Nitride (GaN) is a wide-bandgap semiconductor material with higher breakdown strength, faster switching speed, higher thermal conductivity, and lower on-resistance. Power devices based on GaN significantly outperform silicon-based devices. Due to the significant improvements that GaN offers in switching performance and size reduction, record power density and efficiency can be realized for a multitude of applications contributing to the advancement of energy-efficient and high-performance solutions.

Types of GaN Gate Drivers

Gallium Nitride FET-based power conversion systems offer higher efficiency, increased power density, and lower overall system costs compared to their silicon-based counterparts. These advantageous characteristics have spurred the presence of an ever-expanding ecosystem of power electronics components, including gate drivers, controllers, and passive components specifically designed to enhance eGaN® FET performance.

Low-Side Gate Drivers

Low-side drivers are used to drive ground-referenced switches.

Half-Bridge Gate Drivers

Half-bridge drivers are used to drive two switches connected in a bridge configuration in both floating and ground-referenced switches.

The tables located here show several examples of low-side and half-bridge drivers suitable for use with eGaN FETs.

Driving High-Side Switches

In a simple bridge topology structure with a driving circuit, the source terminal of the upper switch can be floating anywhere from ground to DC bus potential. Therefore, two things are needed for driving high side switches:

- Floating supply — to provide power to any circuitry associated with this floating midpoint potential.

- Level shifter — to transmit the PWM control signal to the floating driver circuitry.

Key Considerations When Selecting a GaN Gate Driver

The gate driver IC plays a crucial role in maximizing the switching speed capabilities of eGaN FETs. To ensure compatibility with eGaN FETs, the gate driver must feature suitable UVLO for 5 V drive, low pull-up and pull-down resistances, a small footprint, and isolation with adequate common-mode transient immunity (CMTI) to withstand high dv/dt. Other beneficial features of some eGaN compatible drivers include integrated voltage regulators, bootstrap management, and very narrow pulse width capability.

GaN Gate Driver Requirements

To meet the demands of high-frequency and high-performance applications, gate drivers for GaN FETs must consider the following factors to achieve optimal performance:

- High-side bootstrap voltage “clamp” – to manage low-side FET reverse current conduction (reverse conduction voltage can reach up to 2.5 V which can charge the bootstrap capacitor to over 7 V) for bootstrap power supply-driven half-bridge drivers.

- Under voltage lockout (UVLO) should be verified and is recommended to be in the range of 3.6 V for disable and 4.0 V for enable.

- Since GaN devices can switch very fast, the gate driver should withstand high dv/dt; a capability > 100 V/ns is recommended.

- The minimum deadtime should be minimized to reduce deadtime losses, ideally within the 20-40 ns range

- A small, low-cost Schottky diode in parallel with the lower FET may be necessary.

- Separate Ron/Roff pins

- Over-temperature limit protection

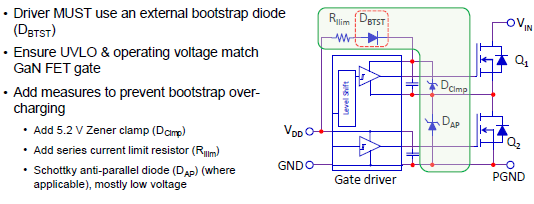

Given these requirements, it is also possible to use a generic MOSFET gate driver IC with GaN FETs using the following modifications.

Key Considerations When Using Controller ICs with GaN FETs

There are situations where designers prefer to use a controller IC with an integrated MOSFET based gate driver. Adapting these drivers to operate with GaN FETs is feasible, provided certain criteria are met. The critical consideration is that the bootstrap diode should be external, and the UVLO setting should align with the requirements for GaN FETs. When modifying a MOSFET-based half bridge gate driver we recommend adding a 5.2 V Zener clamp diode across the bootstrap capacitor, a current limiting resistor in series with the bootstrap diode, and, if applicable, an anti-parallel diode across the lower FET. These combined measures effectively restrict bootstrap overvoltage.

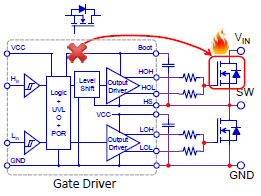

Until now we have relied on a diode, either internal to the gate driver or external, for the bootstrap supply. Gate driver internal diodes exhibit reverse recovery owing to process limitations, resulting in potential losses in the upper FET of a buck converter. To address this, the bootstrap diode can be replaced with a GaN FET, creating a synchronous FET bootstrap supply. The introduction of a GaN FET replaces the function of the bootstrap diode and additionally regulates the bootstrap capacitor, as it can conduct current in both directions. The synchronous bootstrap FET circuit performs optimally at higher frequencies and/or can be used to eliminate switch node voltage transition distortion induced by reverse recovery.

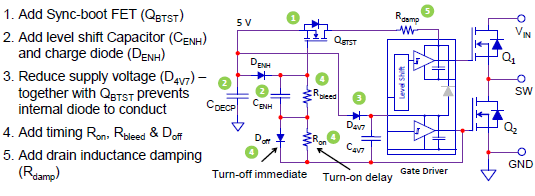

Here are the steps to retrofit a synchronous bootstrap power supply to the gate driver:

- Begin by incorporating the synchronous bootstrap FET, connecting the source to the 5V supply and the drain to the bootstrap capacitor circuit.

- Implement a voltage shift of the lower FET gate signal using a capacitor Cenh and diode Denh to charge this capacitor whenever the low FET gate is held low.

- Slightly reduce the main supply to the gate driver to prevent the internal diode from experiencing perpetual forward biasing. Employ diode D4V7 for this purpose.

- Add the turn-off and turn-on timing circuit, consisting of Ron, Rbleed, and Doff.

- Lastly, introduce damping for the drain circuit inductance using Rdamp.

EPC can recommend the perfect GaN-compatible gate driver to meet your needs. GaN experts at EPC are happy to talk with you about your design specifications and goals to help you choose the right driver. Contact EPC today.