BrightLoop Converters and EPC: Collaborators Pushing the Boundaries of Power Conversion and Facilitating the Energy Transition

GaNの話 – Renee Yawger

1 22, 2024

Efficient Power Conversion and BrightLoop Converters have worked together to combine their respective design expertise, aiming to produce smaller, lighter converters. Over the past six years, this dynamic partnership has not only pushed the envelope in efficient power conversion but also played a pivotal role in advancing the energy transition. The successful collaboration has placed BrightLoop Converters as the lead supplier for eMotorsport vehicles (Formula E, ExtremE, LMDH and others) and also opened opportunities in new markets such as eVTOL and the new generation of aircrafts.

Initial Partnership Leads to the BB SP Converter

BrightLoop’s collaboration with EPC bore fruit with the development of the DCDC BB SP converters. Utilizing the EPC2029 gallium nitride (GaN) FET, BrightLoop Converters managed to reduce the size and cost while enhancing the reliability of its converter. To make the use of BB SP compelling, it must exhibit negligible losses and weight compared to the rest of the system. Thanks to EPC’s GaN FETs, this is achievable. For example, a 48V actuator coupled with BB SP using GaN can be lighter weight than the equivalent 12 V counterpart.

Another important feature, attributable to BrightLoop’s expertise in ultra-high speed digital control, is the capability to implement a closed control loop at 600 kHz the same as the switching frequency. The resulting high bandwidth necessitates very little capacitance, enabling the avoidance of electrolytic capacitors. In the BB SP, only ceramic capacitors are used, reducing further the size and cost while significantly improving reliability.

Development of the HV-LV DCDC Converter Product Line

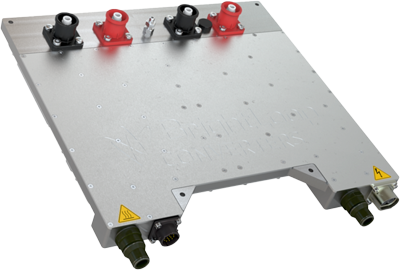

This successful collaboration is enabling the development of BrightLoop’s HV-LV DCDC converter product line, showcasing the best power density on the market.

|

Input Voltage

|

250V to 950V

|

500V to 950V

|

|

Output Voltage

|

10 to 56V

|

15V

|

|

Power limitation

|

105A or 1950W

|

80A or 900W

|

|

Weight

|

590g

|

740 g

|

This product line has become the standard solution for the most demanding applications and thank to its modularity (multiple LV outputs and large range of LV voltage 9 to 56V) has spanned across diverse sectors such as motorsport, aerospace, and defense, solidifying its reputation as a versatile go-to response for high-performance requirements.

HV-LV product line design update

After extensive field testing and successful application in nearly 100 different scenarios, the collaboration between EPC and BrightLoop Converters is reaching new heights.

After extensive field testing and successful application in nearly 100 different scenarios, the collaboration between EPC and BrightLoop Converters is reaching new heights.

For the next generation of converters, BrightLoop Converters has selected EPC's latest QFN-package device, the EPC2302. This strategic choice not only enhances production cost efficiency but also elevates power density, setting the stage for large-scale OEM production. The new generation of converters is designed to deliver higher power levels. The Medium-sized unit is geared to provide 300A/6kW, while the Large-sized unit takes it a step further with an impressive 600A/12kW. Furthermore, these converters will boast a higher voltage, with a maximum working voltage of 80V.

In doing so, BrightLoop Converters and EPC continue their collaborative efforts, developing innovative solutions and applying performance gains to new markets in heavy-duty and mass/industrial production applications. Moreover, this partnership marks a significant technological breakthrough in the electric and hydrogen sectors, aligning with the overarching goal of facilitating the energy transition.

Conclusion

The successful collaboration between BrightLoop Converters and EPC has not only revolutionized power conversion in eMotorsport and high-reliability applications but has also opened doors to broader implications across diverse industries. By continually pushing the boundaries of innovation and optimizing production processes, the partnership has introduced a new era of high-performance, cost-effective, and reliable solutions. As they continue to explore new markets and drive technological advancements in the electric and hydrogen sectors, their shared commitment to facilitating the global energy transition promises a future of enhanced efficiency and sustainability.