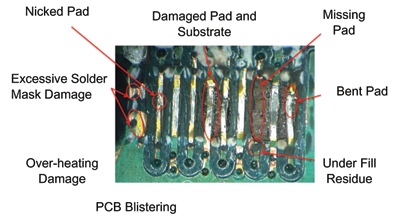

Unacceptable Damage (Board will need to be scrapped):

- Any visible copper pad/trace damage (bending, scoring, buckling, breakage) in the area of the die.

- Any blistering of the PCB – can break internal vias.

- Any scorching of the PCB – can cause voltage breakdown.

- Any excessive mask damage – die is mask defined and needs the mask for proper alignment.

ANY ONE of these conditions present, then scrap the board