The Growing Ecosystem for eGaN FET Power Conversion

GaN Talk – Rick Pierson

May 18, 2019

Prologue

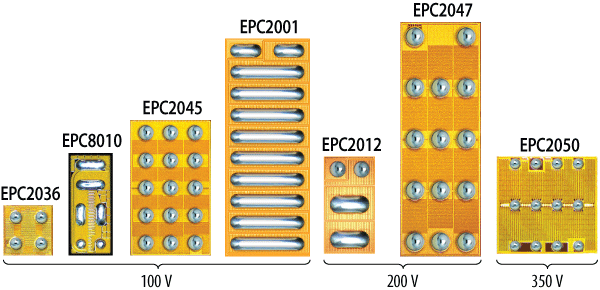

eGaN® FET-based power conversion systems offer higher efficiency, increased power density, and lower overall system cost than Si-based alternatives. These advantageous characteristics have spurred the presence of an ever-increasing ecosystem of power electronics components such as gate drivers, controllers, and passive components that specifically enhance eGaN FET performance. Some examples of eGaN FETs are shown in figure 1.

Figure 1: Examples of eGaN FETs ranging from 7 mΩ through 120 mΩ and from 100 V through 350 V

Figure 1: Examples of eGaN FETs ranging from 7 mΩ through 120 mΩ and from 100 V through 350 VOverview of the eGaN FET ecosystem

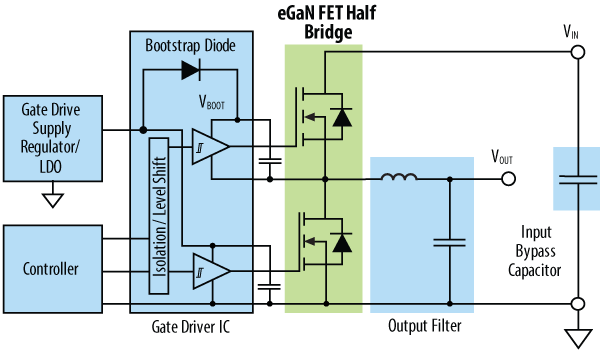

The eGaN FET ecosystem can be broken down into three main categories: 1) gate driver, 2) controllers and 3) passive components. A typical synchronous buck converter, as shown in figure 2, highlights these various components. The requirements for these components are driven by the characteristics of eGaN FETs, such as small footprint, fast switching, tight gate voltage requirement, and high-frequency capability.

Figure 2: Circuit schematic of a typical synchronous eGaN FET based Buck converter, highlighting critical components in the eGaN FET ecosystem

Figure 2: Circuit schematic of a typical synchronous eGaN FET based Buck converter, highlighting critical components in the eGaN FET ecosystemGate drivers for eGaN FETs

The gate driver IC is crucial for maximizing the switching speed capability of eGaN FETs. To be compatible with eGaN FETs, the gate driver must have a suitable UVLO for 5 V drive, low pull-up and pull-down resistances, small footprint, and isolation with sufficient common-mode transient immunity (CMTI) to withstand the high dv/dt. Other beneficial features of some eGaN compatible drivers include integrated voltage regulators, bootstrap management, and very narrow pulse width capability. Table 1 shows some examples of low side gate drivers suitable for use with eGaN FETs and table 2 similarly shows half-bridge gate drivers.

| Texas Instruments |

LM5114 |

No |

General purpose |

Contact EPC |

| Texas Instruments |

UCC27611 |

Yes |

Suitable for use in a half bridge with a digital isolator |

EPC9081 |

| Texas Instruments |

LMG1020 |

No |

Ultra-fast,1 ns pulse width |

Contact EPC |

| uPI |

uP1964 |

Yes |

Integrated adjustable drive voltage regulator |

— |

| IXYS |

IXD_604 |

No |

Dual driver, suitable for large FETs |

— |

Table 1: eGaN FETs compatible low side gate drivers

| Texas Instruments |

LM5113-Q1(NRND)*‡ |

100 |

Yes |

Lo & Hi |

50 |

EPC9078 |

| Texas Instruments |

LMG1205*‡ |

100 |

Yes |

Lo & Hi |

50 |

EPC9078 |

| uPI |

uP1966A*‡ |

80 |

Yes |

Lo & Hi |

— |

EPC9078 |

| uPI |

uP1966B* |

80 |

Yes |

PWM |

— |

— |

| pSemi |

PE29101 |

100 |

Yes |

PWM |

— |

Contact EPC |

| pSemi |

PE29102 |

100 |

No |

PWM |

— |

EPC9204 |

| Texas Instruments |

LMG1210 |

200 |

Yes |

PWM |

300 |

Contact EPC |

| Silicon Labs |

Si8274GB1-IM |

630 |

No |

PWM |

200 |

Contact EPC |

| Silicon Labs |

Si8275GB-IM |

630 |

No |

Lo & Hi |

200 |

Contact EPC |

| Analog Devices |

ADuM4120ARIZ |

1092 V |

No |

Lo or Hi |

150 |

— |

| Analog Devices |

ADuM4121ARIZ |

1118 V |

No |

Lo or Hi |

150 |

— |

| * Footprint compatible ‡ Pin compatible |

Table 2: eGaN FET compatible half-bridge gate drivers

For high voltage designs where no single IC solution exists, low side gate drivers can be used in combination with high voltage signal isolators that feature high CMTI.

Controllers for eGaN FETs

As eGaN FETs push converters to higher frequencies, controllers are required to operate in the MHz range with higher control bandwidth and tighter regulation for high-frequency converters. Many controllers also incorporate a gate driver stage, which must meet the same gate driver requirements previously mentioned. Tables 3 and 4 show eGaN FET compatible controllers for synchronous rectification and synchronous Buck converter applications, respectively.

| NXP |

TEA1993TS |

Yes |

65 ns / 40 ns |

120 |

38 |

| NXP |

TEA1995T |

Yes (Dual) |

80 ns / 40 ns |

100 |

38 |

| NXP |

TEA1998TS |

Yes |

40 ns / 40 ns |

60 |

10.5 |

| ON-Semi |

NCP4305A |

Yes |

35 ns / 12 ns |

200 |

35 |

| ON-Semi |

NCP4308A |

Yes |

40 ns / 20 ns |

150 |

35 |

Table 3: eGaN FET compatible controllers for synchronous rectifiers

| Analog Devices |

LTC7800 |

Yes |

320 kHz - 2.25 MHz |

98% |

60 |

| Microchip |

MIC2127A |

Yes |

270 kHz - 800 kHz |

85% |

75 |

| Microchip |

MIC2103/4 |

Yes |

200 kHz - 600 kHz |

85% |

75 |

| Texas Instruments |

LM5140-Q1 |

Yes |

440 kHz / 2.2 MHz |

95.6% / 78% |

65 |

| Texas Instruments |

TPS40400 |

Yes |

200 kHz - 2 MHz |

95% / 75% |

20 |

| Texas Instruments |

TPS53632G |

No |

300 kHz - 1 MHz |

— |

5 |

| Renesas |

ISL8117A |

Yes |

100 kHz - 2 MHz |

— |

60 |

Table 4: eGaN FET compatible controllers for synchronous buck converters

Digital controllers are also useful for many eGaN FET applications, such as multi-phase and multi-level architectures. Suitable examples include Microchip’s PIC series and TI’s Delfino and Piccolo series.

Passive components for eGaN FETs

The higher operating frequency of eGaN FET based converters requires passive components optimized for higher frequencies.

Key metrics in eGaN FET converter performance are power density and efficiency, which includes the input and output filters. Important inductor selection parameters include low series resistance (ESR) to minimize conduction loss, low core loss, and low parasitic capacitance. Vishay’s IHLP series are well suited to meet these criteria.

Suitable ceramic capacitor selection for the bypass/decoupling are available from multiple vendors where temperature coefficients of X7R or X7S offer excellent results with highest power density.

Conclusion

As eGaN FETs continue to penetrate application designs, the surrounding ecosystem of supporting components needed to achieve the superior performance of eGaN FETs will also grow. Today this ecosystem is no longer a limiting factor in GaN-based designs, and designers have a rapidly increasing number of gate drivers, controllers, and passive component options to choose from.