It was not until the mid-1980’s that the scale of power MOSFET production was big enough to bring the costs of the power MOSFETs in line with bipolar transistors. It was then that IRF made its frontal assault on the bipolar transistor.

The target incumbent was Motorola, as they held the largest share of the bipolar transistor market. As a reaction to the onslaught of the MOSFET, Motorola initially deployed resources to scare potential MOSFET users. These scare tactics included rumors of reliability problems, high prices, and an unreliable supply chain.

Despite these attacks, the power MOSFET continued to gain acceptance into traditional applications where the bipolar transistor had previously held the dominant position. Recognizing the superiority of this new technology, Motorola launched its own power MOSFETs pledging to be agnostic between the two technologies -- “We make both, so buy from us” was their battle cry. The problem was, they didn’t make the best power MOSFETs, and eventually, lost the war between these two semiconductor materials.

Ironically, today power MOSFETs are the “king of the hill,” and GaN-on-Si power devices are the challengers. The early success of these GaN-based power transistors and integrated circuits initially came from the speed advantage of GaN compared with silicon. GaN-on-Si transistors switch is about 10 times faster than MOSFETs and 100 times faster than IGBTs.

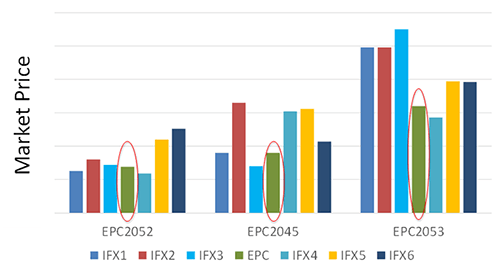

Applications such as RF envelope tracking for 4G/LTE base stations and light detection and ranging (lidar) systems for autonomous cars, robots, drones, and security systems were the first volume applications to take full advantage of GaN’s high-speed switching ability. Since these early applications, the production volumes have grown, and now GaN power devices are at a point where the prices are equivalent (see figure 1) to the slower, bigger and aging power MOSFET components.

Thus, it is time for GaN’s frontal assault!

Figure 1: April 2019 distributor pricing survey result for 100 V rated eGaN FETs compared with equivalently rated power MOSFETs. Inside the red ovals are eGaN FET prices.

Figure 1: April 2019 distributor pricing survey result for 100 V rated eGaN FETs compared with equivalently rated power MOSFETs. Inside the red ovals are eGaN FET prices.

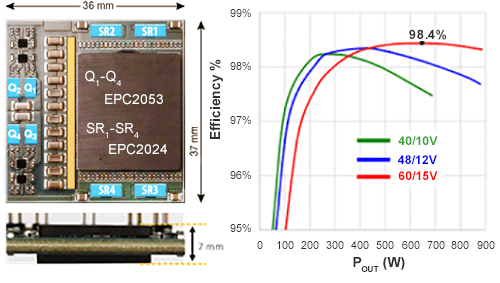

GaN’s first direct competitive assault against silicon MOSFETs came in late 2018 in a battle for 48 V DC-DC power supplies. Due to the significant improvements that GaN offers in switching performance and size reduction, power supply designers realized that GaN FETs could make higher power density and more efficient 48 V power supplies. these supplies are needed in high high-density computing applications for cloud computing, artificial intelligence, machine learning, and gaming applications. Record power density and efficiency could be realized with simple topologies such as the 900 W DC -DC converter using an LLC topology shown in figure 2. A power density of about 1700 W/in3 (104 W/cm3) are is achieved with an overall efficiency above 98%.

Figure 2: This 900 W DC-DC converter uses EPC2053 eGaN FETs on the nominal 48 V primary side and EPC2024 eGaN FETs on the nominal 12 V output secondary side at greater than 98% efficiency.

Figure 2: This 900 W DC-DC converter uses EPC2053 eGaN FETs on the nominal 48 V primary side and EPC2024 eGaN FETs on the nominal 12 V output secondary side at greater than 98% efficiency.

And then the automotive industry started to follow a similar path, opening another very large opportunity for GaN power devices.

Given the growing demand for electronically-driven functions within the vehicle, such as electric steering, electric air conditioning, electric suspension and a multitude of USB-C charging ports within modern cars and trucks, the traditional 14 V power distribution buses have been growing in size and weight at an alarming pace. A mild hybrid car today requires between 2 and 8 kW of electricity to be available. A 14 V, 8 kW distribution system requires wires to conduct 570 A. At 48 V that number is reduced to 170 A, which saves on the need for heavy and hard-to-manage wiring harnesses.

Recognizing the value in moving to a 48 V system, Tier-1 automotive electronics manufacturers are producing or planning to produce 48 V – 14 V bi-directional DC-DC power supplies to accommodate this new electrical architecture while maintaining compatibility with legacy 14 V systems. The simplest, lowest cost and most efficient solution today is the GaN FET-based buck/boost converter such as shown in figure 3.

Figure 3: A 97% efficient, 6 kW 48 V – 14 V bi-directional automotive-grade DC-DC buck/boost converter that uses 16 of EPC’s 100 V eGaN FETs.

Figure 3: A 97% efficient, 6 kW 48 V – 14 V bi-directional automotive-grade DC-DC buck/boost converter that uses 16 of EPC’s 100 V eGaN FETs.

The frontal assault on the power MOSFET has begun!

Today’s GaN FETs are improving rapidly in size and performance. Moreover, the current benchmark devices are still 300 times away from their theoretical performance limits. EPC has been shipping GaN transistors for a decade with over 100 billion hours of field experience with fewer failures than the mature power MOSFET.

Smaller, faster, reliabile, and comparably priced…at this point, there are few reasons not to use GaN FETs and ICs! Incumbent MOSFET producers, recognizing that their products are near their performance limits and a viable competitive solution is gaining traction, are already broadcasting vague warnings – scare tactics – of reliability issues and unreliable supply chains. They cite obsolete GaN pricing and performance comparisons. Already the defensive position that “we can do MOSFETs or GaN, we are agnostic” has reappeared from entrenched silicon manufacturers.

As Mark Twain allegedly said a century ago, “History doesn’t repeat itself, but it often rhymes.”